Palletless & Inline

Description

Sending loads on pallets to destinations where they are handballed out anyway has always been a costly exercise, the only benefit being the initial convenience of loading. If the pallets now need to conform to ISPM15, the extra expense will justify a much closer look at alternatives. The increased cost of wood will only add to the argument.

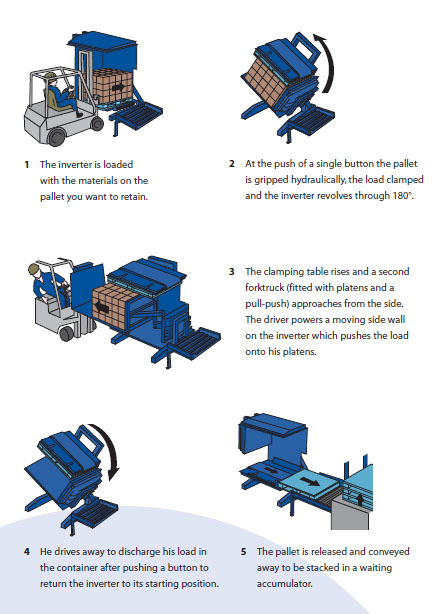

The original Palletless Loading System consists of a 180 degree inverter with a built-in pusher on the sidewall. The pallet is gripped and the load inverted. A forktruck equipped with a pusher attachment and broad platens receives the load from one side and drives into the container to discharge. Meanwhile, the system is reinverting the empty pallet dispatching it to the opposite side and stacking it up.

A simpler alternative is to fit raised ribs to one table of the inverter allowing access by a multi-tyned truck again fitted with a scissor push to discharge the load.

Most of the product handled in Premier's machines, be it milk powder in Ireland, sugar in the UK or boxed fish in Holland, is headed for third-world countries where handballing goods out of a container is commonplace. However, Premier have always been surprised how much travels this way to the United States and other more advanced markets. This indicates that the cost of labour at the destination is outweighed by the saving in space, pallets or other methods of manual loading at the point of origin.

Another concept complimentary to Premier's inverter are the Dutch-built RollerForks. A conventional forklift truck is fitted with two, three or four of these specially designed tynes which are equipped with dual sets of tiny rollers. The load, minus the pallet, is picked off the ribbed table of the inverter and driven into a container. As the truck reverses, the rollers work in opposite directions, one set going backwards on the container floor, the other causing the product to roll off forwards into position.

With any of these systems, the producer has the benefit of the use of conventional pallets in-house and the option to decide at the last moment which product is to be exported and by what method. This flexibility is the key to cost savings and to giving the customer the load in the form they want it.

Most of the different styles of inverter have been integrated into in-line systems at some time or another; even the FS has been installed with conveyor on one table at the end of a line.

The first inverters set up for conveyor-feed were the GL style (now no longer manufactured) which received the pallet load on one side and swung over 180 degrees in an extended see-saw motion, to dispense it on the other. This was fine if every load needed to be turned as nothing could get through the machine without inversion.

The next option was the drum or "Pac Man" inverter which received the load side-on and revolved on electrically driven rollers underneath the body of the machine. It was difficult to clamp and support loads in this model, plus it occupied a great deal of space. This too fell out of favour.

The RR provided answers to many of the problems associated with inline pallet exchange. The load tables could be built to almost any size, ideal for handling large sheets of corrugated board and the clamping range is extensive. Loads which do not need inversion can simply pass through from one side to the other. When it clamps and tips it immediately rises out of the conveyor line so there is no space requirement on either side to allow it to swing. This means the adjoining rollers can butt up to those on the inverter tables.

Future in-line systems will undoubtedly be based on the Pallet Changer principle with loads entering from the side or front onto a set of rollers fitted to the machine's loading table. The pallets will also be ejected and loaded the same way with a pallet stacker and dispenser as part of an integrated system.